X· Neurons — Edge Computing Driven by AI Expert Systems

Model Distillation and Real-Time Edge Processing — Seamless Integration and Smarter Decisions Beyond Protocol Limits.

X·Neurons brings together cross-industry strengths to forge core technologies for smart manufacturing, smart buildings, and smart cities — enabling businesses to fast-track their AI transformation and elevate their key technological capabilities.

X·Neurons Core Technologies

AIoT Edge Computing

Edge AIoT

With real-time data analysis at the edge, Edge AI minimizes cloud dependency and maximizes efficiency and responsiveness.

Expert system

Expert System

Powered by an expert knowledge base and self-learning AI, the system dynamically fine-tunes control strategies to deliver optimized performance.

Ultra-Low Latency Computing

Ultra-Low Latency

Edge computing enables ultra-fast decision-making within milliseconds while ensuring reliable data transmission.

Protocol Auto-Adaptation

Protocol Auto-Adaptation

Supporting 80% of industrial protocol standards, making downstream data integration seamless—not a barrier.

Information security protection

Cybersecurity Protection

With Zero Trust architecture, the focus shifts from perimeter-based defenses to continuous authentication between nodes.

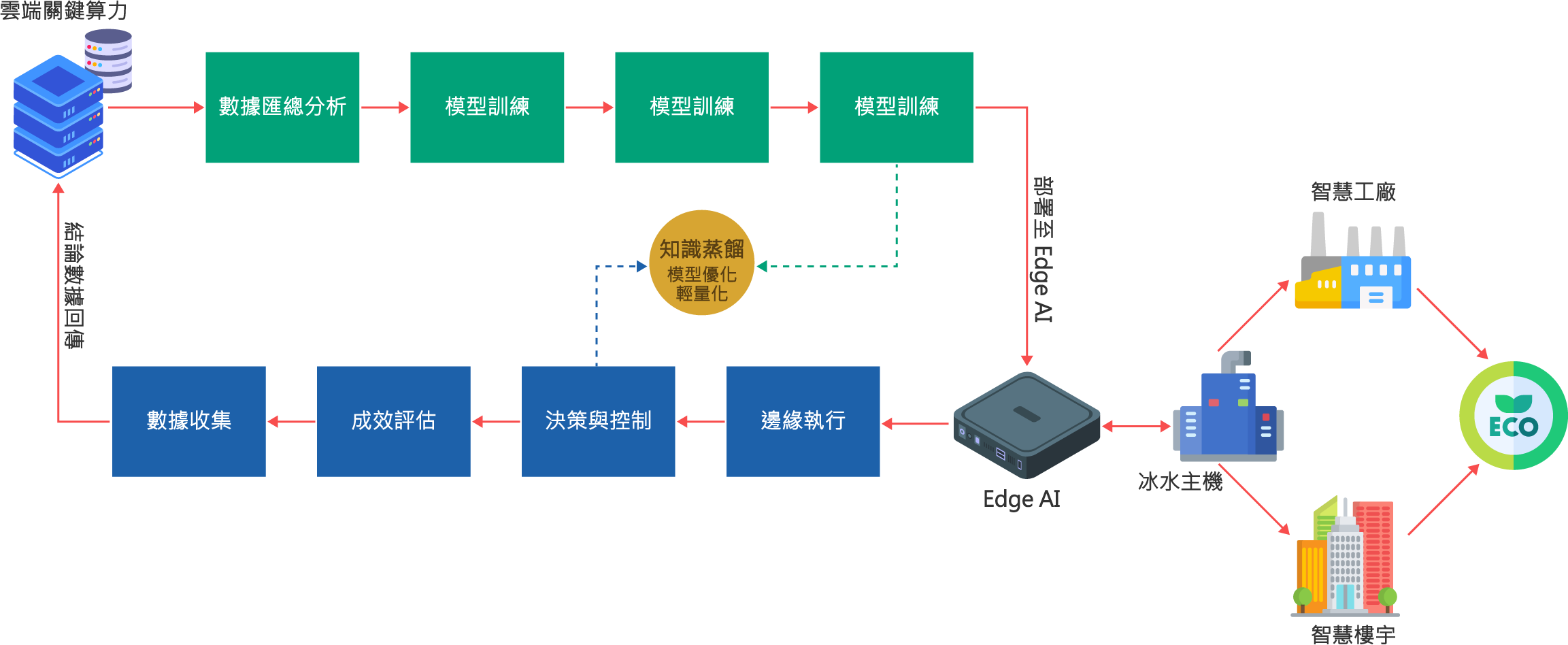

Edge AI Model

Edge AI Model

Through model distillation on high-performance computing platforms, the refined model is deployed to the edge, enabling real-time decision-making and unlocking the full value of time-critical data.

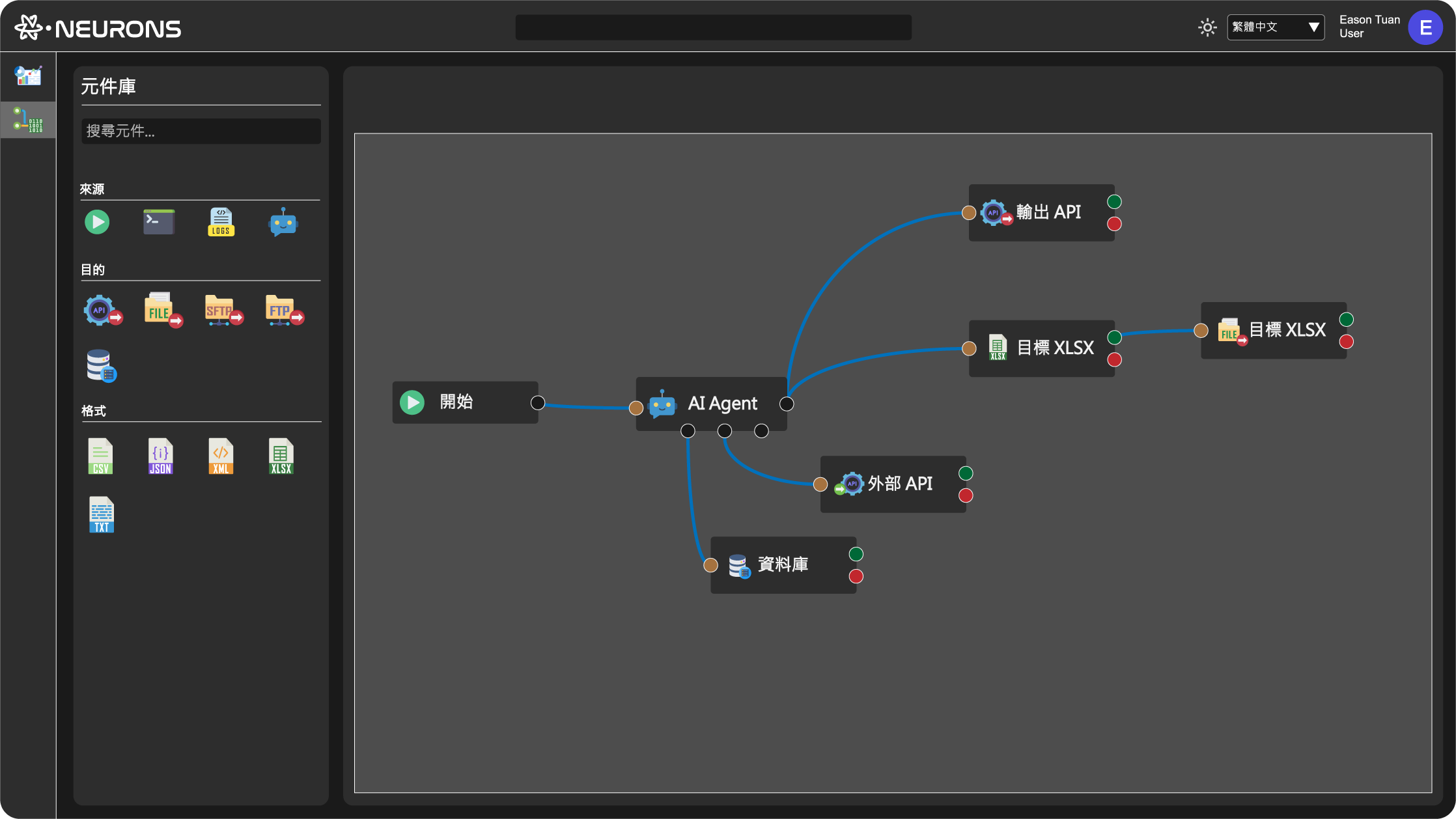

Achieve AI Capabilities Through No-Code Tools

Empowered by workflow logic—free from the constraints of programming languages

Designed with user habits in mind, our intuitive interface lowers the learning curve—empowering businesses to rapidly adopt AI solutions. Paired with a built-in expert system, it provides instant access to optimized control strategies and enables true reverse control capabilities.

Real-World Application: No-Code + Expert System Integration

Chiller systems typically account for 25% to 40% of total energy consumption, significantly impacting energy efficiency and cost control. To address this challenge, we leverage edge AI for real-time decision-making to dynamically adjust operating parameters—ensuring optimal temperature control while reducing unnecessary energy usage.

At the same time, the system maintains the stable temperature conditions required for consistent production quality, minimizing energy waste. Additionally, it intelligently analyzes equipment status to predict maintenance needs, improving workforce deployment efficiency and preventing both over-maintenance and unexpected failures. This ensures stable equipment operation and further enhances overall energy efficiency and operational cost management.